In modern agriculture, pest control is a critical factor in ensuring crop yield and quality. With the growing adoption of sustainable farming practices, insect nets have emerged as an eco-friendly and efficient alternative to chemical pesticides. This guide provides a systematic approach to selecting insect nets, covering scientific principles, material properties, and practical implementation to help farmers and growers create a pest-free, healthy cultivation environment.

I. Insect Nets: Definition and Material Innovation

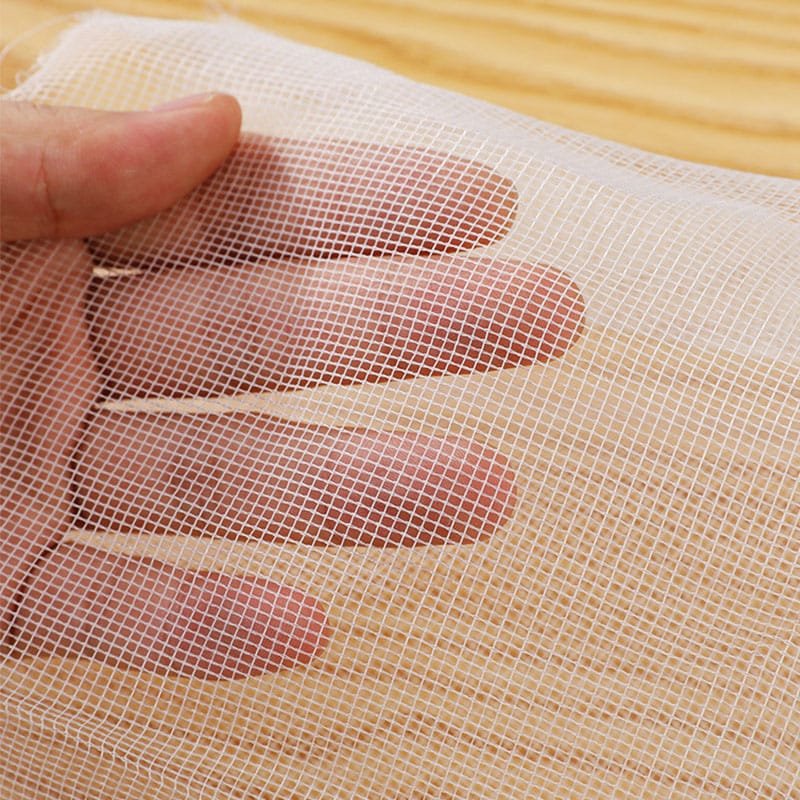

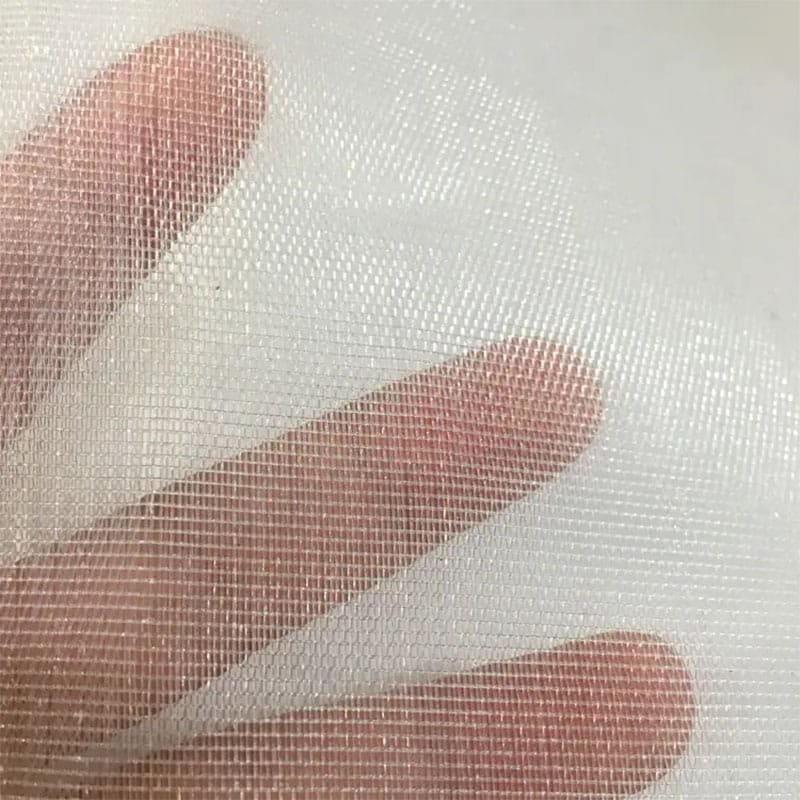

Insect nets are barrier meshes made from high-density polyethylene (HDPE) through precision weaving technology. Their core function is to physically block pests such as aphids, whiteflies, and thrips from reaching crops, while allowing air, sunlight, and moisture to pass through, ensuring optimal plant growth conditions.

Key Material Characteristics

- 100% Virgin HDPE:

- High strength and corrosion resistance with lightweight design for easy installation.

- Excludes recycled plastics to prevent brittleness and mesh deformation.

- UV-Stabilized Treatment:

- Enhanced with UV inhibitors to resist solar radiation, extending outdoor lifespan to 3-5 years.

- Precision Aperture Control:

- Mesh sizes ranging from 40 to 60 mesh adapt to the body sizes of different pests for targeted protection.

II. The Dual Role of Agricultural Insects: From Pests to Targets

Insects play two roles in agricultural ecosystems:

- Beneficial Insects: Bees (pollinators) and ladybugs (aphid predators) maintain ecological balance.

- Harmful Pests: Aphids, whiteflies, and thrips damage crops by feeding on tissues or spreading viruses, leading to yield loss.

Core Value of Insect Nets:

- Physical Barrier: Protects high-value crops like vegetables and fruits while minimizing chemical pesticide use.

- Eco-Friendly: Preserves beneficial insect populations and biodiversity.

III. Proven Effectiveness of Insect Nets: Data and Farmer Feedback

1. Protection Efficiency

- 50-mesh nets block over 90% of aphids, significantly reducing infestation risks.

- 60-mesh nets achieve near-complete isolation of tiny pests like thrips and whiteflies.

2. Added Benefits

- Reduced Pesticide Reliance: Lowers chemical residues, ensuring food safety and soil health.

- Disaster Resistance: Dense weaving buffers hail impact and shields seedlings from strong winds.

IV. Scientific Installation and Scenario Adaptation

1. Installation Steps

- Accurate Measurement: Choose net widths based on cultivation areas (greenhouses, open fields) to avoid gaps.

- Structure Setup:

- Greenhouses: Use existing frames or arches to elevate nets 20-30 cm above crops.

- Open Fields: Deploy “floating row covers” directly over crops, with edges secured by soil.

- Ventilation Management: High-density nets (e.g., 60 mesh) may restrict airflow; integrate side vents or fans for humidity control.

2. Priority Application Scenarios

- High-Value Crops: Organic vegetables, strawberries, and flower nurseries.

- Peak Pest Seasons: Rainy periods or migratory pest outbreaks.

V. Limitations and Mitigation Strategies

- Higher Initial Costs: Long-term savings from reduced pesticide use offset upfront investments.

- Microclimate Effects:

- Dense mesh may reduce light penetration by 10-15%; opt for light-optimized materials.

- Enhance ventilation or pair with shade nets in high-temperature environments.

- Maintenance Needs: Regularly inspect for tears and repair promptly to prevent pest entry.

VI. Mesh Specifications: 40 vs. 50 vs. 60 Mesh

| 40 Mesh | 0.4 | Moths, beetles, birds | Orchards, cornfields |

| 50 Mesh | 0.3 | Aphids, thrips, whiteflies | Leafy greenhouses, fruit farms |

| 60 Mesh | 0.2 | Whiteflies, spider mites | High-value flowers, organic farms |

Selection Principles:

- Balance Protection and Growth: Avoid overly dense mesh that limits light and airflow.

- Target Pest Size: Choose the minimum effective mesh count to avoid overinvestment.

VII. Five Golden Rules for Purchasing Insect Nets

- Material Certification:

- Insist on virgin HDPE; reject recycled materials prone to brittleness.

- Request UV resistance test reports from suppliers.

- Craftsmanship Details:

- Uniform mesh with reinforced edges to resist tearing; opt for ≥50 g/m² fabric.

- Scenario Adaptation:

- Select wind-resistant models for windy areas; antimicrobial coatings for humid climates.

- Supplier Support:

- Prioritize suppliers offering technical guidance, custom widths, and fast restocking.

- Cost-Benefit Analysis:

- Calculate annualized cost per unit area (total price ÷ lifespan) for optimal ROI.

VIII. Future Trends: Smart Integration with Agriculture

- Light-Selective Netting:

- Adjusts light spectra to repel pests while enhancing photosynthesis.

- IoT-Enabled Systems:

- Sensors monitor microclimates, triggering automated ventilation adjustments.

Conclusion

Insect nets are not just barriers—they are pillars of sustainable agriculture. Through scientific selection and meticulous management, farmers can drastically reduce pest-related losses and improve crop quality. As a professional manufacturer, we recommend: target key pests, prioritize material quality, and focus on long-term gains to transform insect nets into invisible guardians of your fields.

Take Action Now: Search for trusted suppliers or contact us for free samples and tailored solutions to elevate your farming practices!

Integrated Keywords: Insect net, UV-resistant, HDPE, 50 mesh, aperture, thrips, lightweight, ventilation, chemical pesticides, custom widths, reinforced edges, microclimate, IoT.