Replacing greenhouse film is not simply covering and fixing it on the greenhouse surface, but requires attention to many details to ensure that the greenhouse film is safely installed on the greenhouse, stably exerts its performance, and prolongs its service life to protect vegetable production. This issue of the facility agriculture special issue will answer your questions about the installation of greenhouse film.

There are many types of greenhouse films. Familiar with the characteristics to choose the right film

For facility vegetables, greenhouse film is an indispensable agricultural input, and its quality largely determines the yield and quality of vegetables. Depending on the raw materials used, common greenhouse films include polyethylene (PE) greenhouse film, polyvinyl chloride (PVC) greenhouse film, ethylene-vinyl acetate copolymer (EVA) greenhouse film, and PO film.

Polyethylene (PE) Greenhouse Film

PE film feels relatively soft, and the new film has good light transmittance, but its weather resistance and thermal insulation are relatively poor. In actual production, anti-aging agents, drip-free agents and other additives need to be added to improve the performance of the greenhouse film. Its life is generally 1 to 2 years. In the production of greenhouse vegetables, most polyethylene films are replaced in winter and spring. After replacing the greenhouse film, the light transmittance is the highest, the damage is less, the heat preservation capacity is strong, and the temperature rises quickly in the greenhouse, which is suitable for early spring vegetable production. Because the greenhouse film has poor fog and dripping properties, it is easy to condense water droplets, which affects the light transmittance, reduces the greenhouse temperature, and increases the humidity in the greenhouse. Therefore, it is not suitable for winter vegetable production.

Polyvinyl Chloride (PVC) Greenhouse Film

This type of greenhouse film has good light transmittance, heat preservation, and weather resistance. The new film has a full light transmittance of more than 85%, high tensile strength, and strong wind resistance. However, the specific gravity of this type of film is relatively large. For greenhouses of the same area, its usage is 1/3 more than that of polyethylene. At the same time, the greenhouse film is easy to harden and brittle at low temperatures, and easy to soften and relax at high temperatures. Although the new film has good light transmittance, after the precipitation of the additives, the film surface absorbs dust over time, is not easy to clean, and the light transmittance deteriorates.

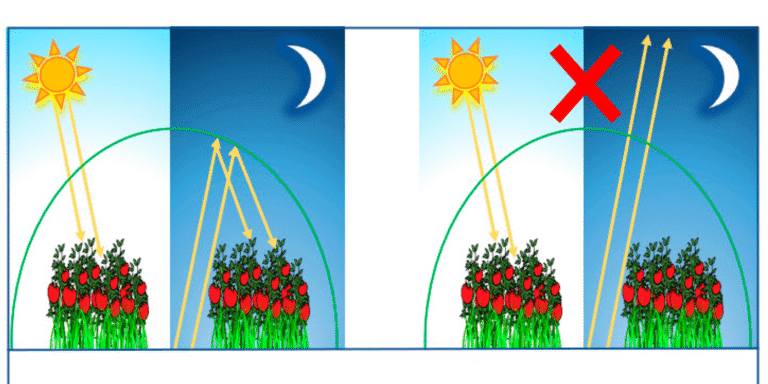

PVC greenhouse film has low infrared transmittance and good heat preservation at night, which is its biggest advantage. It also has the characteristics of easy repair, good dripping resistance, and strong light resistance. PVC greenhouse film is more commonly used in greenhouses with high insulation requirements.

Ethylene-vinyl acetate copolymer

(EVA) Greenhouse Film

EVA film has good toughness, impact resistance, excellent heat preservation, dust resistance and super aging resistance (more than 18 months), and good light transmittance, with a light transmittance of more than 92%. Although it has the performance of dripping and defogging, it only lasts for 4-6 months. Beyond this time, the dripping and defogging function gradually disappears, so it is generally replaced once a year. The higher the transparency of the EVA film, the better. There will be no dripping and fogging phenomenon during the effective time of dripping and defogging.

Polyolefin (PO) Greenhouse Film

PO film is a high-end functional polyolefin agricultural film made of polyolefins. It has good light transmittance, continuous defogging, dripping, and heat preservation.

In particular, the film has been specially processed with fog and dripping technology, which can be maintained for a long time until the film is replaced. It has strong tensile strength, is not easy to penetrate, and is not easy to deform. Especially under high temperature conditions, the properties of PO film are more stable.

Do these points to make the film safe on the shed!

Grasp the time for changing the film

For light-loving vegetables such as tomatoes, the light saturation point is above 40,000 lux. It is best to replace the film in September when the light is relatively strong. For vegetables that like medium light or weak light, such as peppers and beans, the film replacement time can be appropriately delayed, and it is more suitable from the end of September to October.

In addition, the shed film has a certain degree of stretchability. In a high temperature environment, the shed film may be stuck together. If the temperature is too high and the stretch is too large, the shed film will become thinner, especially the part of the shed film in contact with the frame is prone to aging and cracking, affecting the service life. If the temperature is too low, it is not easy to stretch. When the temperature is high, the shed film becomes loose, and it is easy to damage the shed film in windy weather. Therefore, it is best to change the film at around 9 am on a sunny and windless day. At this time, the temperature inside and outside the greenhouse is not much different from that outside, which has little impact on the growth of vegetables in the greenhouse.

At the same time, changing the film during the windless time can prevent the wind from scratching the greenhouse film during the film changing process. In addition, try to shorten the film changing time to prevent some pests from taking the opportunity to fly into the greenhouse, thus burying hidden dangers for the spread of some diseases.

Be cautious in installing the greenhouse film step by step

When changing the greenhouse, the greenhouse film should be carried out in the order of flattening, tightening, pressing and fixing. It is best to use the film pressing rope to fix it, and it is not advisable to use the binding and fixing method of penetrating the greenhouse film with iron wire. The greenhouse film should be evenly tightened in various places to prevent horizontal wrinkles, which is easy to produce dripping. Avoid dragging the greenhouse film back and forth, wear the greenhouse film coating functional layer, and cause local dripping. Do not stretch the film forcefully, causing the coating functional layer to be damaged and affecting the dripping and defogging functions. At the same time, pay attention to the difference between the front and back of the agricultural film products. The words read outside the greenhouse are on the front side, and do not buckle them upside down.

In addition, the greenhouse film at the front corner of the greenhouse is the most vulnerable to damage. Vegetable farmers should set the “pants” with steel wire on the film at the front corner. In addition to continuing to undertake the work of stretching, the thickness of the film is also increased, that is, one layer becomes three layers. This not only greatly reduces the degree of wear of the greenhouse film between the film pressing rope and the steel wire, but also improves the resistance to wear of the greenhouse film by the covering. It should be noted that this “pants” is accurately set at the front corner. It is necessary to have accurate measurements of the greenhouse surface and the width of the greenhouse film, and multiple people should accurately stretch the greenhouse film when applying the film, otherwise it will bend, resulting in the “pants” not falling accurately at the corner.

Fix the film pressing rope and fix the greenhouse film

After replacing the new greenhouse film, the film pressing rope should be pressed in time to prevent the greenhouse film from being damaged by strong winds. When performing the film pressing operation, cloth strips or other objects can be placed under the film pressing rope to reduce the damage to the greenhouse film caused by the film pressing rope and the frame. In addition, the greenhouse film near the film pressing rope should be checked frequently, and wounds should be sealed in time. At present, some vegetable farmers use thick nylon ropes as film pressing ropes. The thickness of thick nylon ropes reaches 0.6 cm-0.8 cm, and the contact area with the greenhouse film is large, so the damage to the greenhouse film is smaller.

For the arch greenhouse, the nylon rope film pressing method can be adopted. Row-by-row fixing means that the greenhouse film is fixed with a film pressing bamboo pole on each main frame, and then the nylon rope is used to press the film between the rows. The advantage of this fixing method is that it has a better fixing ability for the greenhouse film and strong resistance to natural disasters. The nylon rope has a certain degree of elasticity, and the damage to the greenhouse film after compaction is small. The steel wire film pressing method can also be used for interlaced fixing. Interlaced fixing means that when the film is fixed with a film pressing bamboo pole, one row is fixed every other main frame, and then the steel wire is used to press the film. Some vegetable farmers may add two additional short bamboo poles to the main frame of the row at the top of the arch greenhouse for fixing. The advantage of this fixing method is that there are relatively few film pressing bamboo poles used for fixing, the damage area to the greenhouse film is small, and the greenhouse film is protected to the greatest extent.

Be careful when changing greenhouse film Don’t let diseases “take advantage of the opportunity”

Currently, we have entered the peak period of greenhouse film change. After autumn, although the temperature gradually drops, there are relatively many sunny days and strong light during the day. After changing the new greenhouse film, the light transmittance of the new film is above 90%. Changes in environmental conditions will promote the occurrence of diseases such as leaf curling, fruit cracking, and sunburn. Vegetable farmers are advised to prevent them in advance.

Choose the right time to change the film. It is best to change the film at 8 or 9 o’clock in the morning on a sunny and windless day, and try to shorten the film change time.

Pay attention to ventilation and watering. Before changing the film, pay attention to watering in advance to ensure the humidity in the greenhouse, and apply functional fertilizers such as microbial agents and chitin with water, combined with foliar spraying rich in chelated calcium, boron and other trace elements, to promote root and leaf growth, ensure sufficient nutrient absorption, and improve plant resistance. After changing the film, pay attention to strengthening ventilation, and appropriately shade and cool down around noon when the light is strong to avoid drastic changes in environmental conditions.

Spraying pesticides in advance to prevent pests Spraying biological pesticides such as matrine and pyrimidine before changing the film can not only kill insects, but also reduce the occurrence of viral diseases. In addition, after changing the film, pay close attention to pests in the shed. In addition to hanging sticky insect boards and shade nets, spray pesticides in time for prevention and control. For butterfly and moth pests, you can choose avermectin, indoxacarb, chlorantraniliprole, etc. For aphids and whiteflies, you can choose spirotetramat, pymetrozine, imidacloprid, etc.; for thrips, you can choose ethyl spinetoram, cypermethrin and other pesticides; for mites, you can choose spirodiclofen and thiamethoxam, etc., alternate the use of drugs, kill insect eggs, and use silicone additives to improve the effect of the drugs.